Blog

Testing at the Darcy Center

With the Covid pandemic, there is a clear need for testing face masks for consumers. However, the standard certified tests for medical/surgical masks are expensive. This is partly due to the fact that they are also testing for resistance to blood droplets etc. As a result, there is a need for a simple test that can give a first-order indication of the efficiency of consumer masks. Here we set out to develop a simple test that uses low-cost standard components and can be reproduced by anybody, i.e., open-source hardware/software. For example, we have used a standard particulate matter sensor (commercial price 40 Euro), which can detect aerosol droplets from 0.3 µm onward, which is in the range of a virus. Based on these low-cost elements, two setups have been developed, i.e., an aerosol filtering and a breathing resistance test. Hence based on these tests one can get a first-order impression of the efficiency of a particular consumer face mask. However, there is a third axis, i.e., the comfort wearing of a face mask. A good functioning face mask with no-comfort will not be used by consumers.

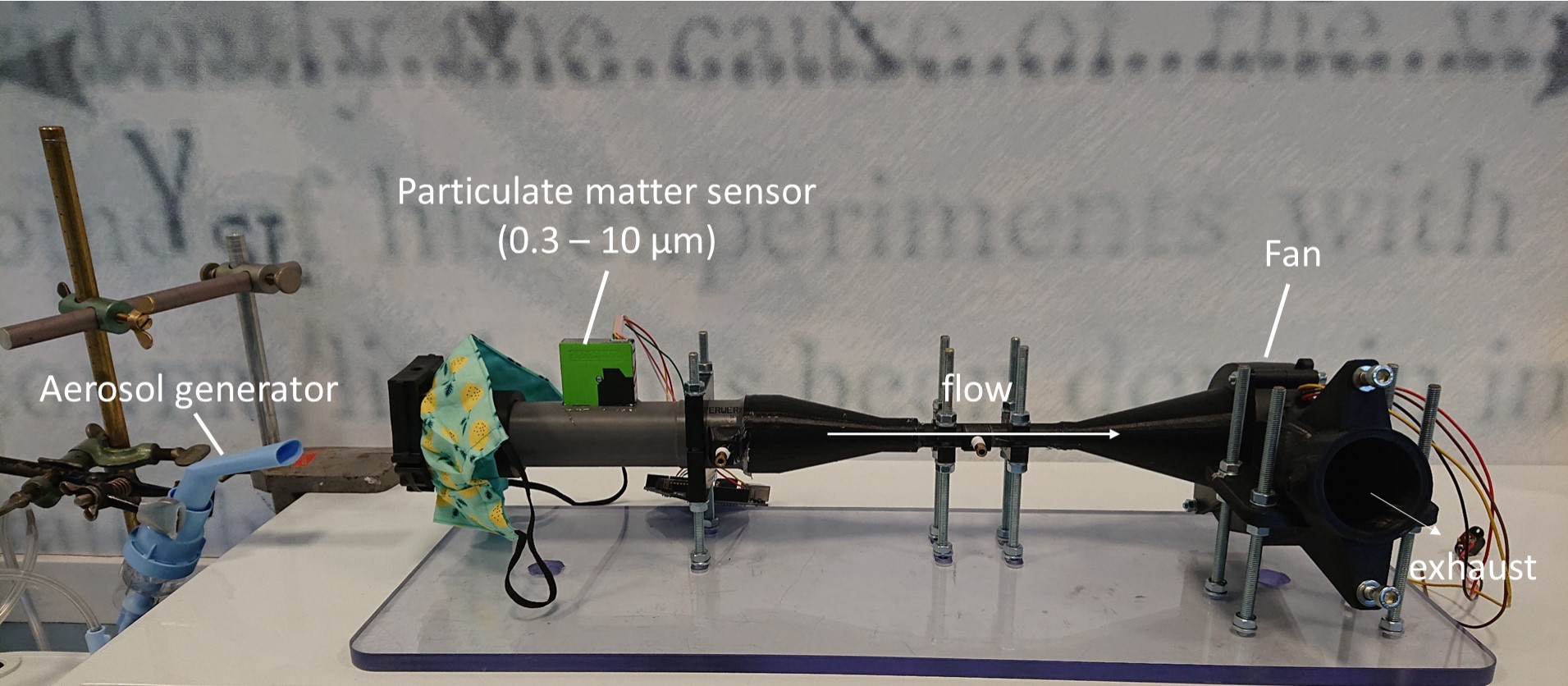

Aerosol Filtering Test

In this test, we determine the efficiency of aerosol filtering of a face mask. Using a standard consumer nebulizer an aerosol stream of a 1% NaCl solution is generated. Using a fan this aerosol stream is sucked through the face mask. Using a standard particulate matter sensor we measure the particle distribution which passes through the face mask. The measurement principle of this industrial sensor is based on laser scattering. By measuring the particle penetration before and after, we can get a relative measurement of the efficiency of a face mask.

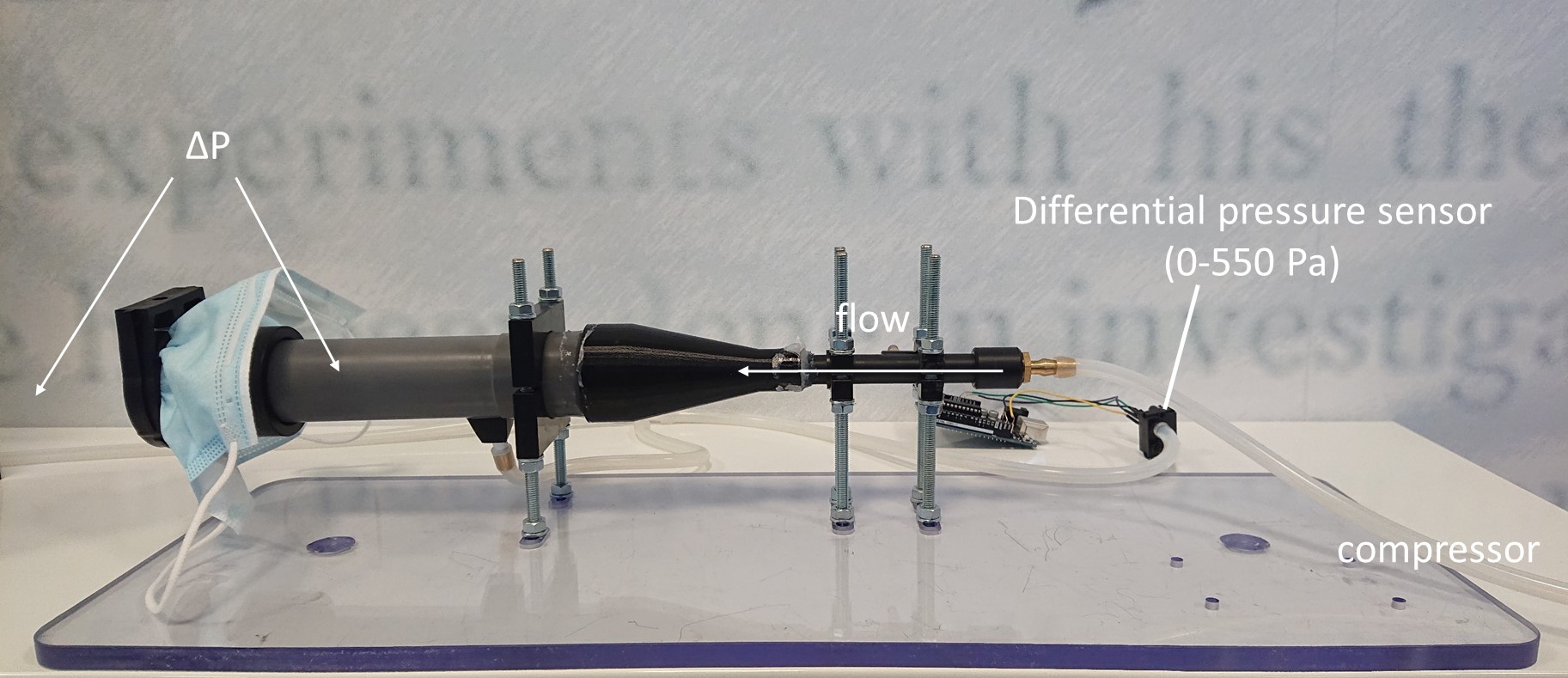

Breathing Resistance

In this test, we determine the breathing resistance of a mask by measuring the pressure difference of a face mask as generated during a flow. In order to generate the flow, we make use of a standard low-cost pressure generator. Using a low-cost differential pressure sensor we measure the pressure difference. In order to compare the various masks, we compare the resistance to a standard medical face mask.

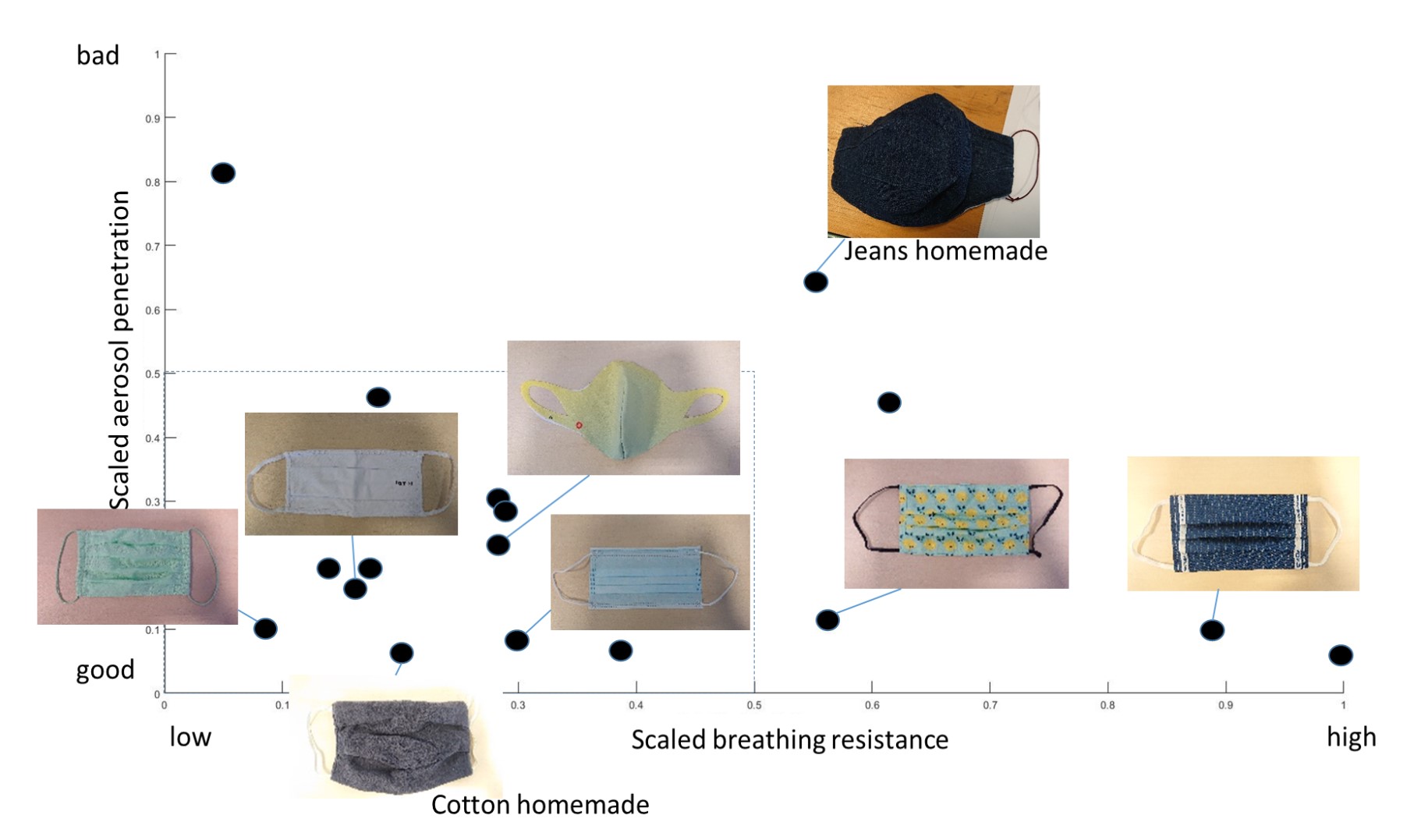

Results

Based on these 2 measurements we can plot the scaled aerosol penetration and the scaled breathing resistance for various face masks. We can distinguish roughly 4 categories:

ideal face mask: good aerosol penetration protection and low breathing resistance good face mask: good aerosol penetration protection and high breathing resistance (probably seen as low comfort for the consumer) bad face mask: bad aerosol penetration protection with high/low breathing resistance

Author: Kevin Vos